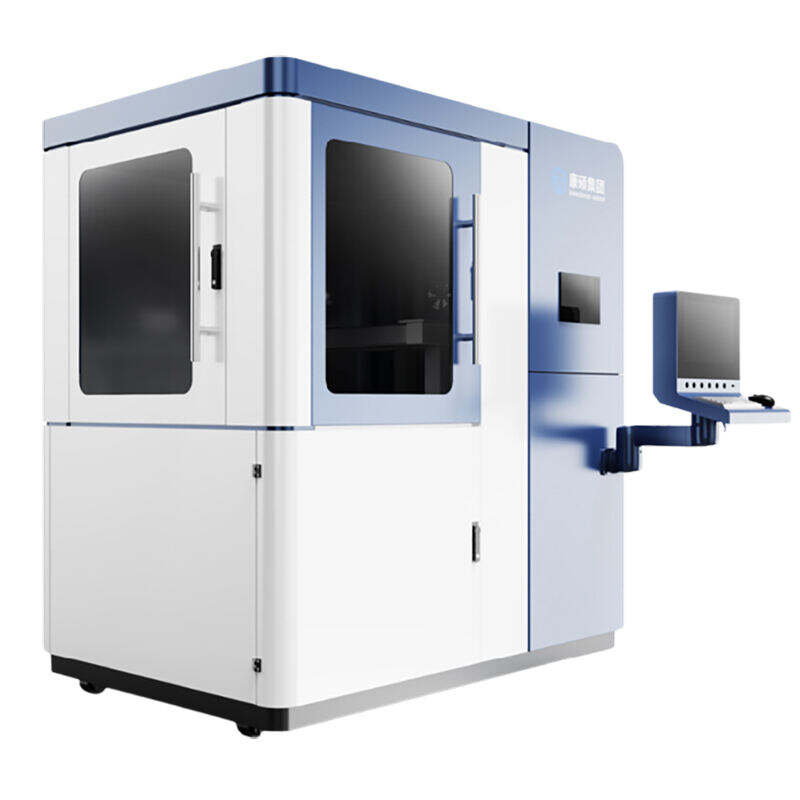

sand printer

A sand printer represents a groundbreaking advancement in industrial manufacturing technology, combining traditional foundry methods with modern digital precision. This innovative device utilizes computer-aided design (CAD) software to create intricate three-dimensional sand molds through a layer-by-layer printing process. The printer operates by depositing thin layers of specially formulated sand mixed with a binding agent, which is then selectively hardened according to the digital design. The technology enables manufacturers to produce complex casting molds without the need for traditional pattern making, significantly reducing both time and costs associated with traditional foundry processes. These machines can create molds with internal geometries and complex shapes that would be impossible to achieve through conventional methods. The sand printer's precision and reliability make it particularly valuable in industries such as automotive, aerospace, and heavy machinery manufacturing, where it can produce molds for engine blocks, transmission cases, and other complex metal components. The system's ability to directly print molds from CAD data eliminates the need for pattern storage and reduces the potential for human error in the mold-making process. Additionally, the technology allows for rapid prototyping and small-batch production, making it an invaluable tool for product development and customized manufacturing solutions.