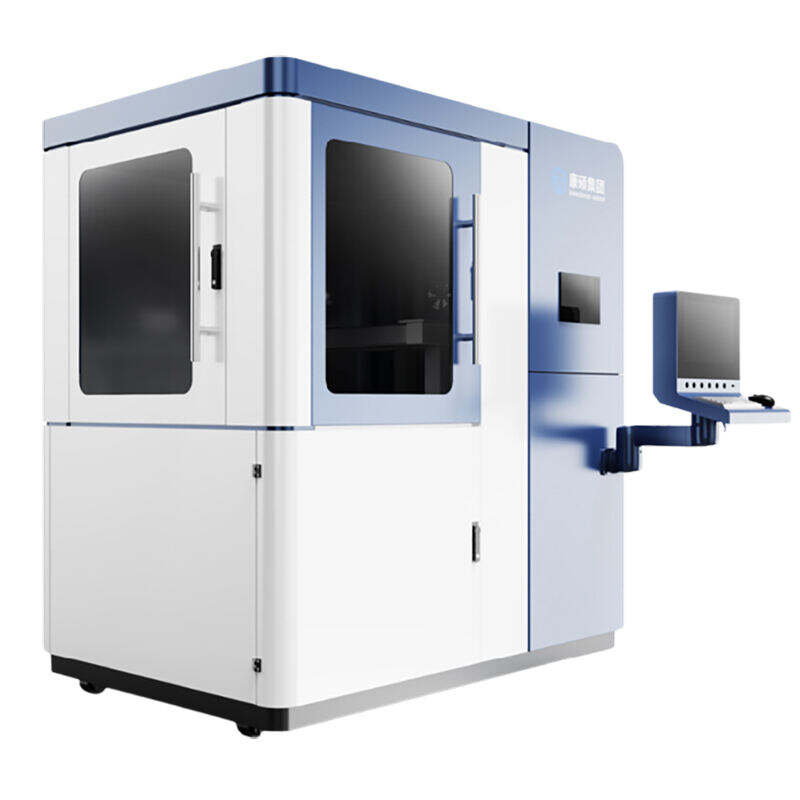

3d sand printer

A 3D sand printer represents a groundbreaking advancement in manufacturing technology, combining traditional foundry practices with modern digital fabrication. This innovative machine creates complex sand molds and cores directly from CAD designs, eliminating the need for traditional pattern making. The printer operates by depositing thin layers of specialized foundry sand, typically 0.3 to 0.5 mm thick, and selectively applying a binding agent through multiple print heads. The binding process occurs layer by layer, gradually building up the desired mold or core shape. These printers can produce intricate geometric designs that would be impossible or extremely difficult to achieve through conventional molding methods. The technology incorporates advanced features such as real-time monitoring systems, automated material handling, and precise temperature control mechanisms. The build chamber can accommodate large-scale components, with some industrial models featuring build volumes of up to 4000 x 2000 x 1000 mm. The printing process is fully automated, requiring minimal human intervention once the print job begins. These machines typically achieve printing speeds of 60-80 mm per hour in the vertical direction, making them suitable for both prototype and production runs. The resulting sand molds exhibit excellent dimensional accuracy, surface finish, and structural integrity, making them ideal for casting various metals including aluminum, iron, and steel alloys.