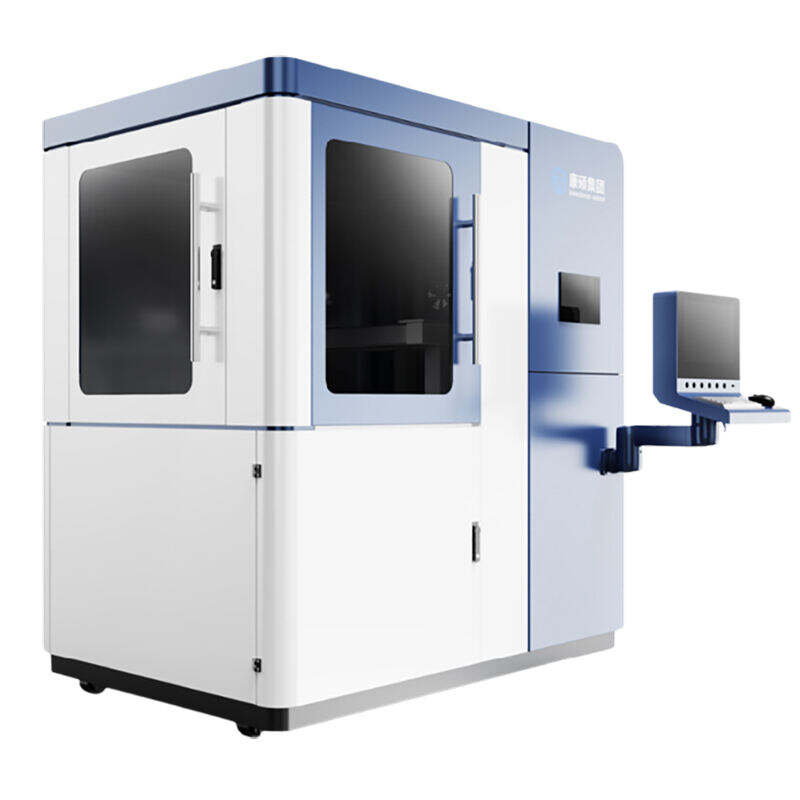

3d sand printing machine

A 3D sand printing machine represents a groundbreaking advancement in manufacturing technology, specifically designed for creating complex sand molds and cores used in metal casting. This innovative system employs additive manufacturing principles to build three-dimensional sand structures layer by layer. The machine utilizes a combination of industrial-grade silica sand and a specialized binding agent, precisely deposited through a print head that moves across a build platform. The technology operates by spreading thin layers of sand, typically 0.3-0.5mm thick, while simultaneously applying a binding agent in specific patterns determined by the digital design. The process continues iteratively, with each new layer building upon the previous one until the complete mold or core is formed. These machines can produce intricate geometries that would be impossible or extremely difficult to achieve through traditional molding methods. They offer exceptional dimensional accuracy, with tolerances as precise as ±0.3mm, making them ideal for producing complex casting components. The technology supports various sand types and binder systems, allowing for customization based on specific casting requirements. Modern 3D sand printing machines are equipped with advanced control systems that monitor and adjust printing parameters in real-time, ensuring consistent quality throughout the build process. They typically feature build volumes ranging from 800x500x400mm to 4000x2000x1000mm, accommodating both small precision parts and large industrial components.