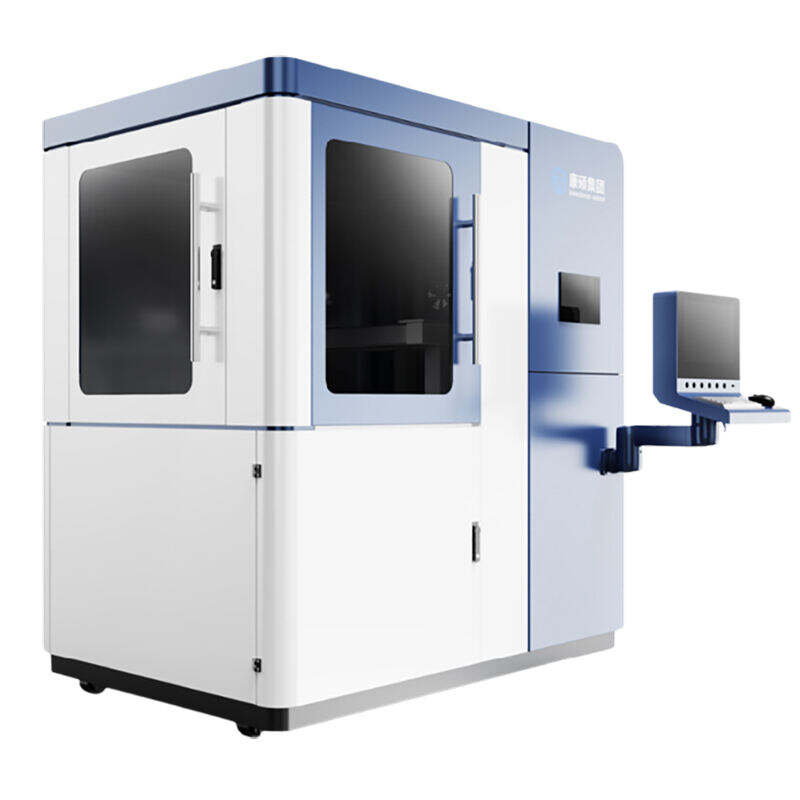

sand mold 3d printer

A sand mold 3D printer represents a revolutionary advancement in foundry technology, combining traditional casting methods with modern additive manufacturing. This innovative machine creates complex sand molds directly from digital designs, eliminating the need for traditional pattern making. The printer operates by depositing layers of specially formulated sand mixed with a binding agent, precisely controlled by advanced software to create intricate mold cavities and cores. The technology utilizes industrial-grade silica sand and environmentally friendly binders, ensuring both quality and sustainability in the casting process. The printer's build chamber can accommodate various sizes, typically ranging from small components to large industrial parts, with exceptional dimensional accuracy of up to 0.3mm. Its automated operation system includes multiple print heads that work simultaneously, significantly reducing production time compared to conventional methods. The machine incorporates real-time monitoring systems and quality control features, ensuring consistent mold quality throughout the printing process. This technology has found widespread applications in automotive, aerospace, and heavy machinery industries, particularly for prototyping and small-batch production runs.