H-1 Factory Building, Mingshan Industrial Park, Gaoping Economic and Technological Development Zone, Jincheng City, Shanxi Province, China. +86-15921818960 [email protected]

The Binder Jetting 3D High-Speed Printing Equipment for Sand Molds consists of a lightweight body, bidirectional high-speed sand spreading system, binder jetting system, printing work chamber, auxiliary system, electrical control system, and human-machine interface system.

The equipment dimensions are 4500mm × 2170mm × 3460mm, with a maximum printing mold size of 1800mm × 1000mm × 700mm, and the printing mold accuracy can reach ±0.3mm. The structure is compact and orderly, with intelligent and efficient functionality.

The bidirectional high-speed sand spreading system can achieve a reciprocating high-speed sand spreading of 400mm/s. The wide-format, high-efficiency printing system can achieve high-speed, high-efficiency printing at 1200mm/s with a 520mm wide printing width.

| Technical Data | Details |

| Dimensions (LxWxH) | 4500x2170x3460mm |

| Molding Range (LxWxH) | 1800x1000x700mm |

| Sand Laying Method | Bidirectional sand laying |

| Printing Resolution | 400dpi |

| Printing Layer Thickness | 0.3mm - 0.6mm |

| Number of Nozzles | 8 (1024 nozzles per head) |

| Max printing speed | 1200mm/s |

| Power Supply Requirements | Three-phase 380VAC ±10%, Frequency 50-60Hz |

| Heating Power | 9KW |

| Total Weight | 5.4T (including one working box) |

| Max Printing Efficiency | 160-270L/h |

| Consumables | Furan resin or phenolic resin, curing agent, silica sand, ceramic sand |

| Number of Working Boxes | Single working box with independent drive |

| Sand Processing Center | Automatic sand processing + any ratio mixing of old and new sand |

| Host Peak Power | 11KW |

| Noise | <60 decibels |

| Environmental Requirements | Operating Temperature 22-38°C |

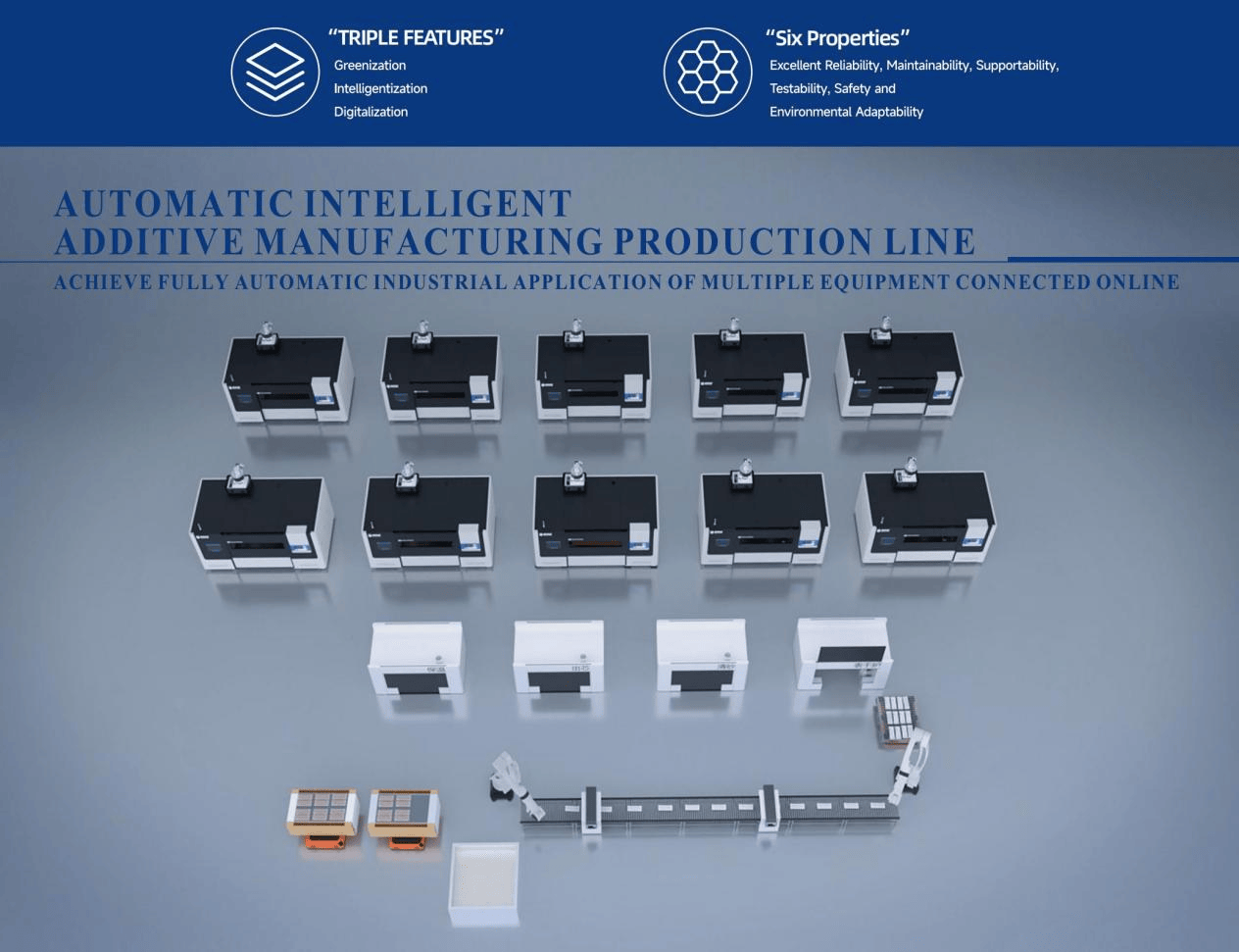

The AGV guided vehicle can precisely position the printing work chamber and automatically move in and out of the equipment. The automatic sand supply system can efficiently and accurately perform sand suction, mixing, and dispensing with precise quantitative sand supply.

The synchronized sand spreading/printing system enables seamless, efficient connection of sand spreading and printing. The system is highly integrated, achieving a maximum printing efficiency of 270L/h per unit.

The automatic logistics system facilitates the automation and intelligent core group line formation. The equipment operates autonomously, enabling unmanned operation throughout the entire printing process.

The software is independently developed and features a variable layer thickness printing function. This equipment is highly automated and intelligent, easy to use as a standalone unit, and convenient for multi-equipment line integration. It is at a leading level in China and advanced globally.