wet sand 3d print

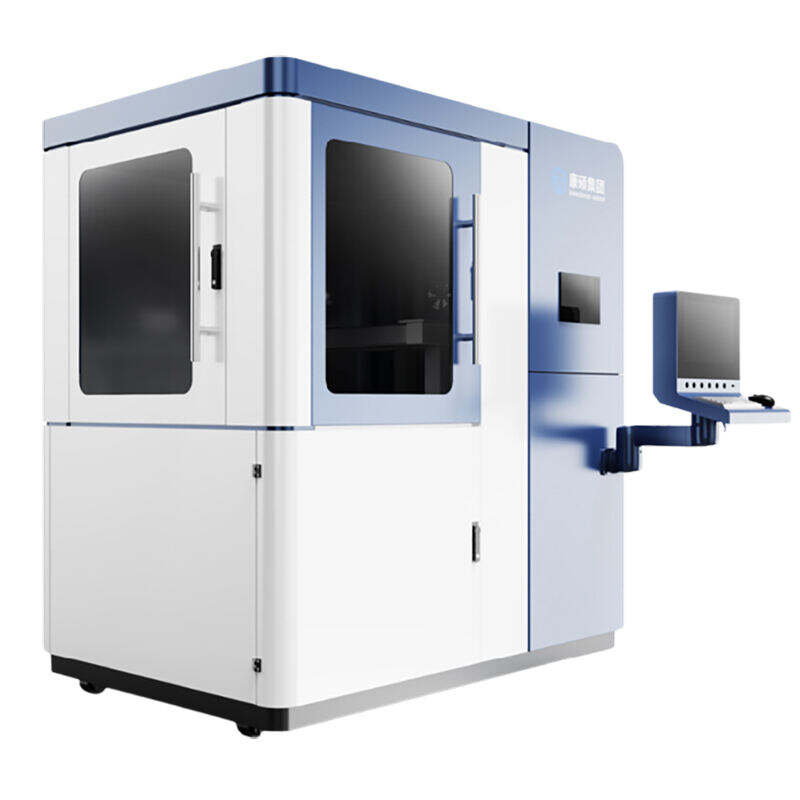

Wet sand 3D printing represents a groundbreaking advancement in additive manufacturing technology, specifically designed for creating complex sand molds and cores for metal casting. This innovative process combines traditional foundry techniques with modern digital fabrication methods. The technology utilizes a specialized binder jetting process where a liquid binding agent is precisely deposited onto layers of sand particles, creating intricate three-dimensional structures. The printer head moves across a bed of sand, selectively depositing the binder according to the digital design, while subsequent layers are built up to form the complete mold or core. This method allows for the production of highly detailed sand molds without the need for traditional pattern making or tooling. The technology accommodates various sand types and binder systems, enabling manufacturers to optimize their casting processes for different metal alloys. With build volumes typically ranging from small parts to large industrial components, wet sand 3D printing has become an essential tool in modern foundries, particularly for prototyping and small-batch production runs.