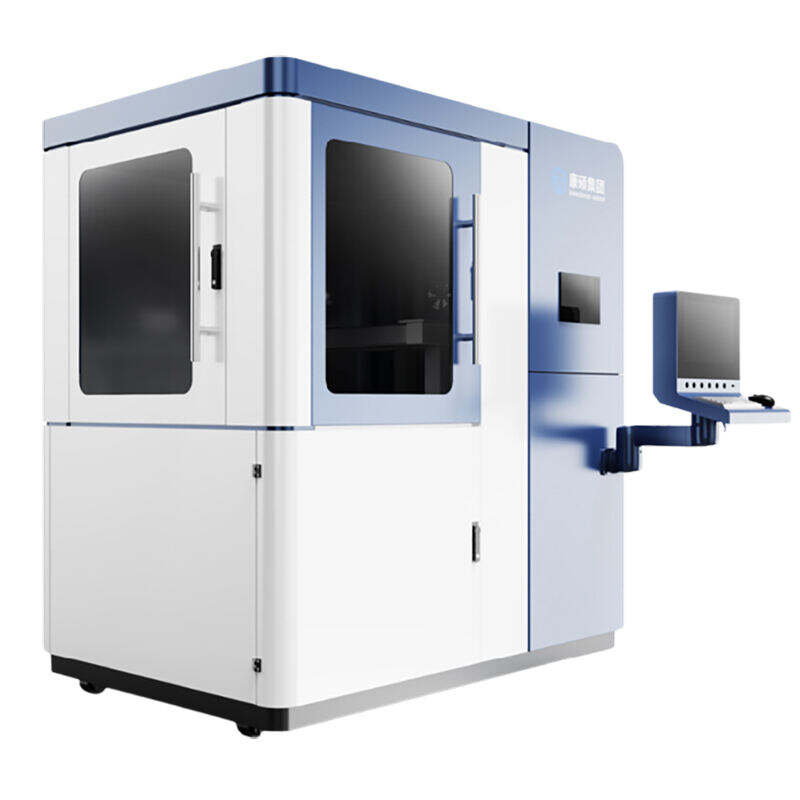

3d sand printing process

3D sand printing represents a revolutionary advancement in manufacturing technology, combining traditional foundry practices with modern additive manufacturing. This process utilizes specialized 3D printers to create complex sand molds and cores directly from digital designs, eliminating the need for traditional pattern making. The process begins with a CAD model, which is digitally sliced into thin layers. The printer then deposits layers of specially treated sand, selectively applying a binding agent through print heads to create the desired shape. Each layer is approximately 0.3mm thick, allowing for exceptional detail and precision. The printer moves systematically, building the mold layer by layer until completion. This technology enables the production of intricate geometries that would be impossible or extremely difficult to achieve through conventional molding methods. The process accommodates various sand types and binder systems, making it versatile for different casting applications. The resulting molds can be used for casting various metals, including aluminum, iron, and steel. This technology has found widespread application in automotive, aerospace, and industrial manufacturing sectors, particularly for prototyping and small-batch production. The entire process is computer-controlled, ensuring high repeatability and precision while significantly reducing lead times compared to traditional methods.