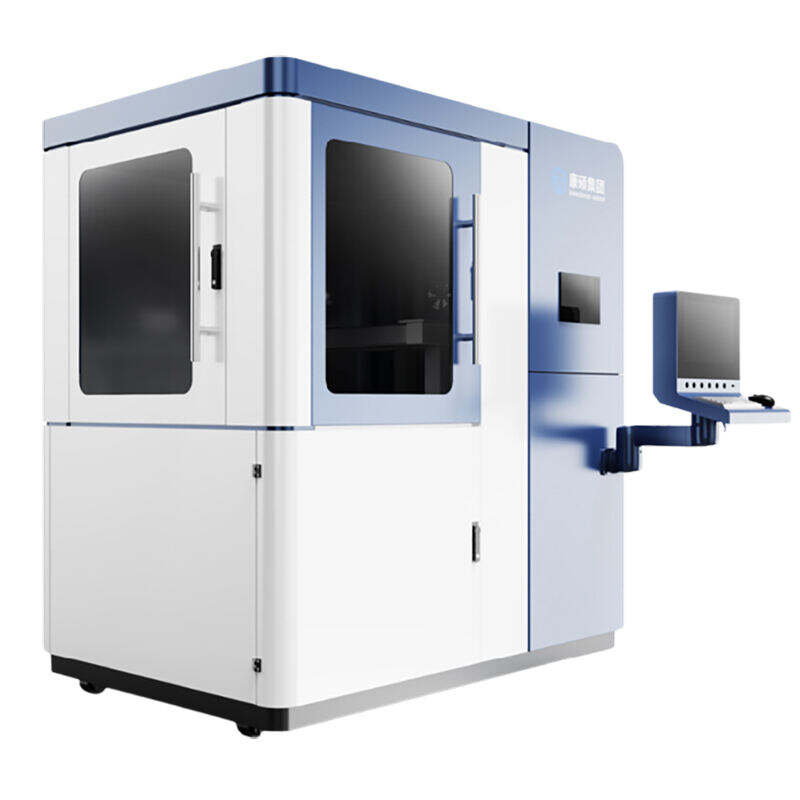

sand 3d print

Sand 3D printing represents a revolutionary advancement in additive manufacturing technology, specifically designed for creating complex sand molds and cores for metal casting. This innovative process utilizes specialized binder jetting technology to precisely deposit liquid binding agents onto layers of foundry sand, creating intricate three-dimensional structures layer by layer. The technology enables the production of highly detailed sand molds without the need for traditional pattern making or tooling. The process begins with a CAD model, which is digitally sliced into thin layers. A recoater spreads a uniform layer of sand across the build platform, followed by selective application of a binding agent through industrial printheads. This sequence repeats until the complete mold or core is formed. The technology accommodates various sand types and binder systems, allowing for customization based on specific casting requirements. The printed molds can be used for casting a wide range of metals, from aluminum to iron and steel, making it particularly valuable for prototyping and small-batch production in automotive, aerospace, and industrial manufacturing sectors.