H-1 Factory Building, Mingshan Industrial Park, Gaoping Economic and Technological Development Zone, Jincheng City, Shanxi Province, China. +86-15921818960 [email protected]

In the wave of digital transformation in the manufacturing industry, the foundry sector has ushered in a spring of technological innovation. Traditional foundry workshops, facing intensified market competition and diversified demands, have turned to intelligent manufacturing transformation and digital upgrading as one of the main directions.

In this journey of transformation, the introduction of the 3D sand mold printer has been like a stroke of genius, injecting vitality into the path of change. More and more customers are introducing this technological tool into their foundry workshops. It has not only accelerated their digital pace but also played a crucial role in the process.

Case Study of a Manufacturing Brand:

Background: The brand's products are renowned for their high performance and reliability, with exquisite designs that meet a variety of fluid transport needs and are widely used in multiple sectors such as energy, industry, and petrochemicals.

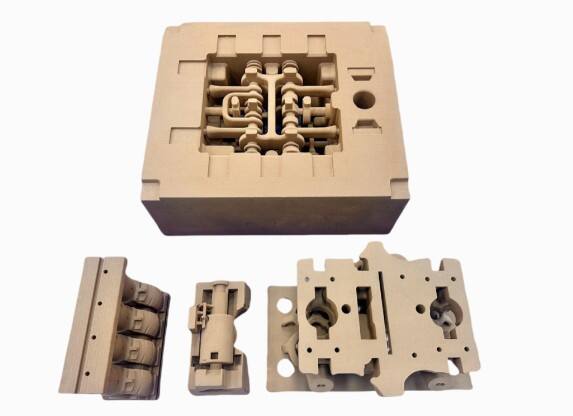

Transformation: Since the introduction of the sand 3D printer, there has been a significant increase in the production efficiency of sand cores. Additionally, the capability to independently carry out medium and small batch production has eliminated the lengthy mold-making time and high mold costs, enhancing its casting production capacity. The move towards intelligence and digitalization has also enabled a faster response to market demands in the future.

It is evident that before the introduction of 3D sand mold printers, foundry workshops mainly relied on traditional manual molding methods, which were not only time-consuming and labor-intensive but also struggled to handle complex or customized orders. The application of 3D sand mold printers has enabled a rapid transformation from design drawings to physical sand molds, significantly reducing the production cycle and improving production efficiency.

This has also brought the following advantages:

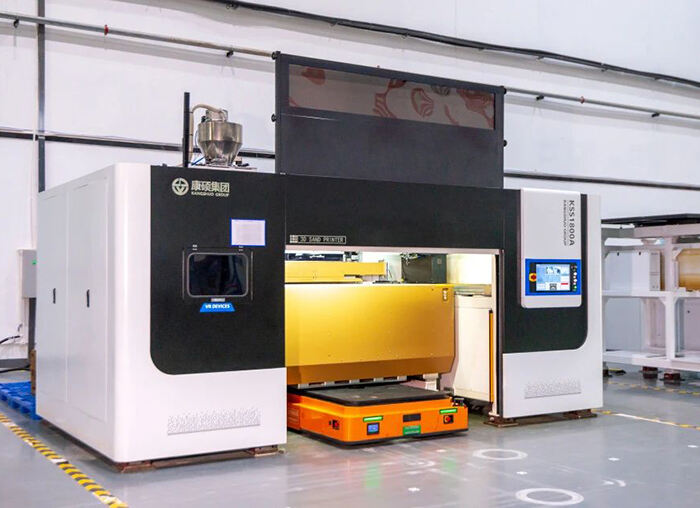

Kangshuo's high-speed sand mold 3D printer, the KSS1800A, employs bidirectional printing technology to significantly enhance printing efficiency, meeting the diverse needs of customers. It features the following main characteristics:

1.High precision - with a printing resolution of 4000 Pi and sand mold accuracy at CT7 level.

2.Flexibility - the printing working box can be freely detached from the machine, facilitating line logistics.

3.Compact size - it occupies only 15 square meters of floor space, greatly saving equipment installation area.

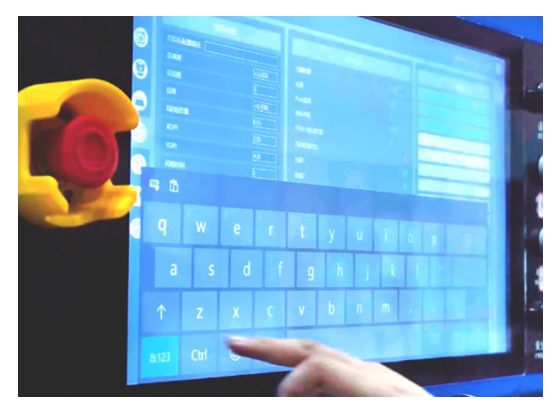

4.Digitalization - it is digitally interconnected with production line equipment, forming an integrated line design and production。

The significance of 3D sand mold printers in the digital transformation of foundry workshops cannot be overlooked. They not only increase production efficiency and casting quality but also reduce environmental impact and production costs, while providing support for intelligent production management and technological innovation. As competition in the casting industry intensifies and customer demands become more diversified, 3D sand mold printers will become an essential choice for industrial digital transformation.