H-1 Factory Building, Mingshan Industrial Park, Gaoping Economic and Technological Development Zone, Jincheng City, Shanxi Province, China. +86-15921818960 [email protected]

Sand printing, also known as 3D sand printing or additive sand manufacturing, is an innovative process that combines traditional sand casting techniques with modern 3D printing technology. This method has revolutionized the way sand molds and cores a...

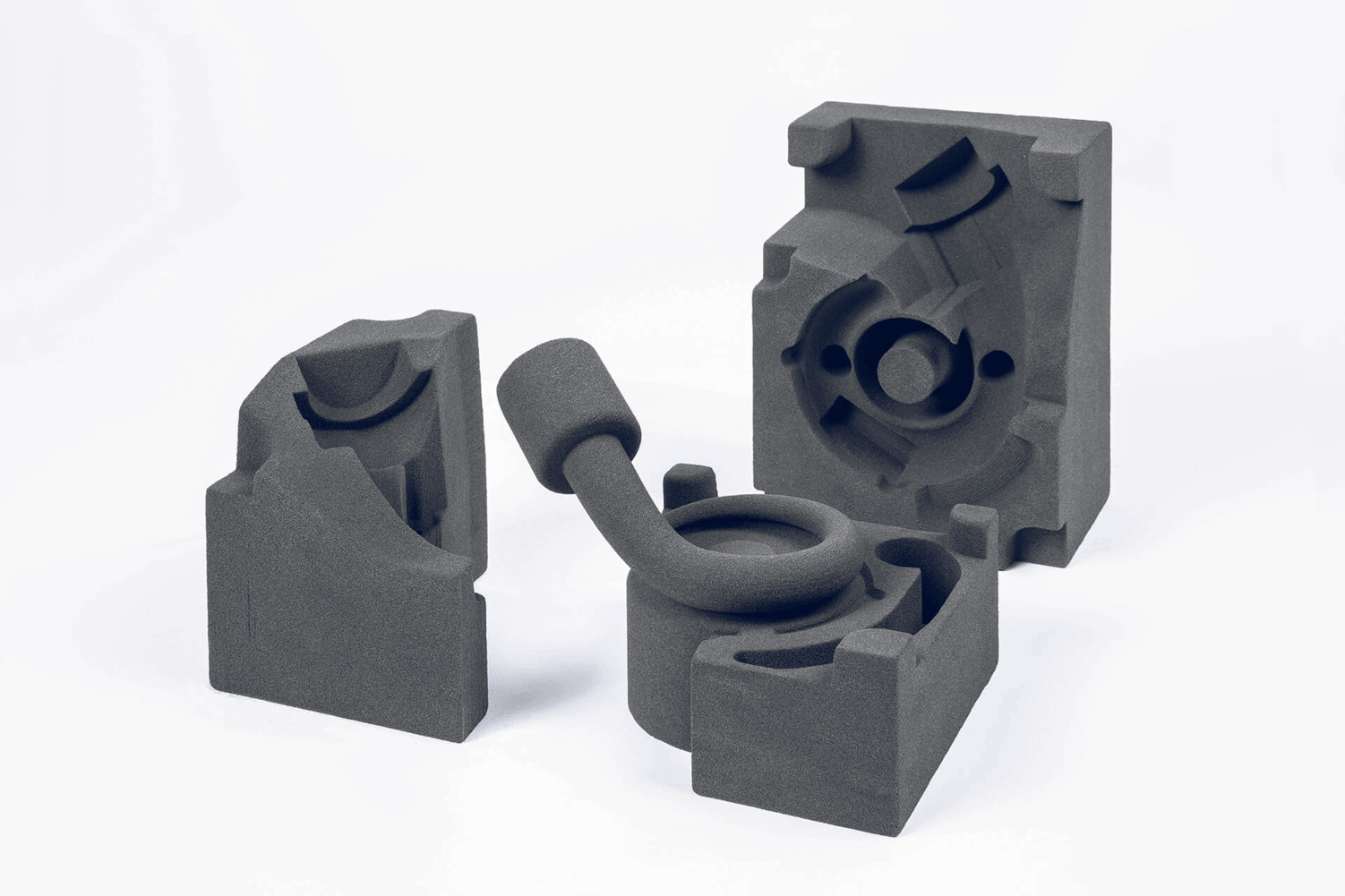

Sand printing, also known as 3D sand printing or additive sand manufacturing, is an innovative process that combines traditional sand casting techniques with modern 3D printing technology. This method has revolutionized the way sand molds and cores are produced, offering significant advantages in design flexibility, production efficiency, and cost savings.

Process of Sand Printing

3D Modeling: The process begins with the creation of a digital 3D model using specialized software such as SolidWorks or UG. This model includes all necessary design features, including parting surfaces, draft angles, and machining allowances. The model is then converted into a file format suitable for 3D printing, such as STL.

Sand Printing: The 3D printer deposits layers of sand material (typically quartz sand or resin-bonded sand) and selectively applies a binder to bond the sand particles together. This layer-by-layer process builds up the sand mold or core according to the digital model. The printed sand mold is then subjected to post-processing steps, such as removing excess sand and reinforcing weak areas.

Casting Preparation: The printed sand molds are assembled and placed in casting equipment. The metal is melted and prepared to meet the required casting temperature and composition.

Casting and Cooling: The liquid metal is poured into the sand mold cavity, ensuring it fills completely. After cooling and solidification, the sand mold is removed to reveal the final casting.

Post-Processing: The casting is cleaned, polished, heat-treated, and machined as necessary to meet the final product specifications.

Advantages of Sand Printing

High Design Flexibility: Sand printing allows for the production of highly complex geometries and internal structures that are difficult or impossible to achieve with traditional sand casting. This includes intricate cooling channels, curved passages, and detailed surface features.

Reduced Production Time: By eliminating the need for physical pattern making, sand printing significantly reduces the production cycle. Design modifications can be made quickly and inexpensively, allowing for rapid prototyping and iteration.

Cost-Effective: Sand printing reduces material waste and labor costs associated with traditional sand casting. The precise material deposition also improves overall material utilization.

Improved Precision and Quality: The 3D printing process ensures high dimensional accuracy and smooth surface finishes, reducing the need for post-casting machining. This results in better overall casting quality and fewer defects.

Environmental Benefits: Sand printing produces less waste and uses fewer chemicals compared to traditional methods, contributing to a more sustainable production process.

Applications of Sand Printing

Sand printing is particularly beneficial in INDUSTRIES that require complex parts and rapid production cycles. Key applications include:

Automotive: Production of engine blocks, cylinder heads, and transmission cases.

Aerospace: Manufacturing of turbine blades, aircraft structural components, and other high-performance parts.

Energy: Production of components for gas turbines and power generation equipment.

Medical Devices: Customized implants and prosthetics.

Future Directions

Despite its many advantages, sand printing still faces challenges such as limited build volume and material selection. Ongoing research and development aim to address these limitations and further expand the capabilities of sand printing technology. As the technology continues to evolve, sand printing is expected to play an increasingly important role in modern manufacturing, offering greater efficiency, precision, and sustainability.

In summary, sand printing represents a significant advancement in the field of casting, combining the precision and flexibility of 3D printing with the robustness and reliability of traditional sand casting.